Your Trusted Industrial Pump Supplier

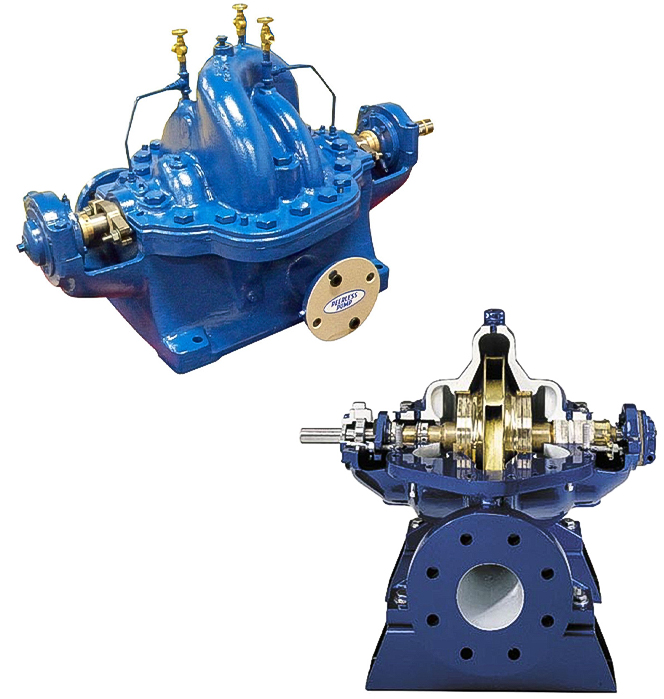

Horizontal split-case pumps economically reduce thrust loads and ensure high efficiency with minimal power consumption, making them ideal for high-volume applications. These centrifugal pumps’ rugged yet simple design is well-suited for low-viscosity liquids such as clear water and unsaturated wastewater in industrial water treatment plants and other diverse applications.

End-suction and inline pumps are expertly engineered for medium-duty service, delivering maximum value for booster systems and general circulating services. From clear water to corrosive chemicals, these versatile and durable industrial pumps can be configured to handle a range of pump applications.

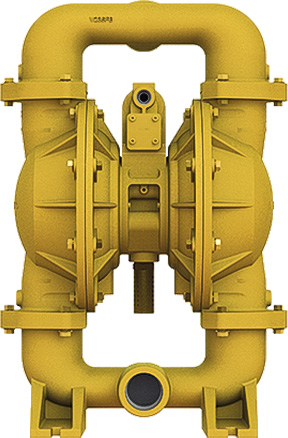

Diaphragm pumps are designed for transferring low, medium, and high-viscosity liquids. These versatile industrial pumps can handle aggressive chemicals, volatile fluids, and liquids containing large solids while maintaining efficiency and optimal performance.

Vertical pumps are ideal for lifting water from lakes, rivers, and reservoirs to support mining operations, agricultural irrigation, municipal water supply, and industrial processes requiring increased pressure. Built for continuous operation, these pumps deliver reliable performance under demanding conditions.

Solids-handling pumps are durable industrial pumps designed to move abrasive wastes, thick slurries, and other challenging fluids. With rugged construction, these pumps ensure reliable performance in wastewater treatment, mining, and other demanding industrial environments.

Engineered Pump Systems

Floating pump systems (barges) are unique, fully assembled, engineered pump solutions that rest on the water’s surface and rise or fall with changing water levels, extending the operational life of the equipment. These systems deliver efficient and consistent performance for municipal lagoons, mine dewatering, drought relief, and other industrial water pump needs.

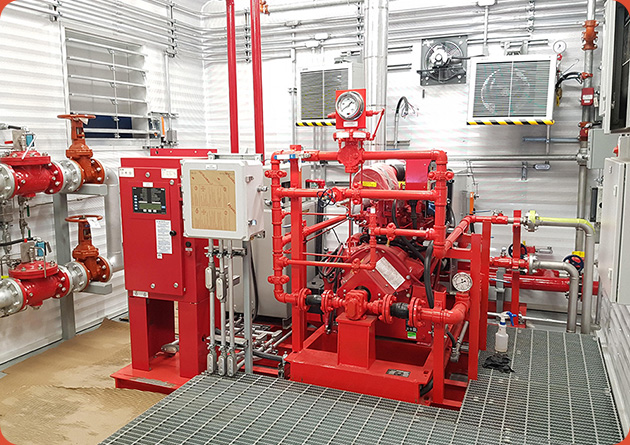

Fire pump systems feature modularized engineered pumps that provide reliable fire protection for industrial projects and municipal facilities. Chamco’s fire pumping systems are manufactured to local and NFPA standards to minimize risk. Additionally, these fire pump systems are delivered fully assembled to reduce on-site labour and construction time.

Fuel pump systems provide a reliable solution for unloading, dispensing, and distributing fuel on-site. Built as modular units, Chamco’s fuel pump systems enable simplified electrical connections and single-point piping. Each station is constructed on a complete skid or within a shipping container and comes with full integrated electrical controls.

Water pump systems are ideal for pond and river intake, low and high-pressure booster stations, and potable water treatment plants. Chamco’s industrial water pump stations are housed in a pre-engineered, all-weather module with a complete electrical scope. These systems can be equipped with fire, chemical, and leak detection instrumentation to ensure durability and peak performance.

Pit dewatering systems are pre-engineered to provide reliable intake for pit sump pumping, perimeter well pumping, and surface water pumping, ensuring efficient fluid management in demanding conditions. Chamco’s pit dewatering systems are delivered in a self-framing building with full electrical scopes, BAS, PLC, HVAC, DCS, and pump instrumentation for long-term performance.

Wastewater submersible lift stations are engineered to pump sewage and wastewater from lower to higher elevations with the highest wire-to-water efficiency available. Chamco provides submersible pumps and lift stations that deliver superior performance, quality, and cost-effectiveness compared to the competition.

The Chamco Advantage

Pump Installations

Chamco provides reliable installations for industrial pumps and engineered pump systems. Whether or not your equipment was purchased from Chamco, our technicians have the expertise to install and support centrifugal pumps, vertical turbine pumps, diaphragm pumps, and other pumps for your unique requirements.

Industrial Pump Service

At Chamco, we have over six decades of experience helping our customers ensure the continued effectiveness of their pumps and pump systems through around-the-clock service, preventative maintenance, and rebuild services.

Industrial Pump Parts

Chamco supplies heavy-duty pump components and compressor parts designed for long-lasting performance across various industrial applications and business needs. With Chamco, you can enjoy benefits such as:

From 6 locations across Western Canada, we service the following areas:

British Columbia

Burnaby

Creston

Delta

Drayton Valley

Fort St. James

Fort St. John

Kamloops

Kootenays

Langley

New Westminster

Okanagan

Prince George

Prince Rupert

Richmond

Sparwood

Sunshine Coast

Surrey

Vancouver

Vancouver Island

Alberta

Athabasca

Calgary

Camrose

Canmore

Cold Lake

Drumheller

Edmonton

Evansburg

Fort McMurray

Fort Saskatchewan

Grande Prairie

High Level

Hinton

Leduc

Lethbridge

Lloydminster

Medicine Hat

Nisku

Peace River

Red Deer

Rocky Mountain House

Slave Lake

St. Paul

Stettler

Turner Valley

Wainwright

Whitecourt

Wood Buffalo